Factory visit at Hatvan-based Bosch plant

We visited the Bosch Group´s automotive electronics manufacturing unit in Hatvan, Hungary. Have a look at our gallery and summary of facts about the production plant.

In 1999, production of transmission control modules began at Robert Bosch Elektronikai Kft.'s plant, established a year earlier. By now, the company has produced over 100 million products from 250 product families and 38 product groups.

|

Last year, the Bosch Group's Hatvan-based plant was expanded with a 2,000 square metre area to 92,000 square metres. 100 new workstations were opened in the new office wing, today housing the plant's procurement and logistics activities.

|

The Hatvan-based plant has had a number of milestones to celebrate last this year: 10 million dashboard units, 35 million onboard control units and 60 million sensors. In addition, the company will celebrate the 15th anniversary of the start of production at the plant in 2014.

|

The average age of workers at the Hatvan plant is 33 years. The company's employees are transported to the plant from the area within 60 km radius with 60 buses. Parts of comfort, drivetrain and safety systems are manufactured on the production lines.

|

The plant has been producing engine control units since 2006. The first products were delivered to BMW. Today the company manufactures 10 million parts per year, which means that every eighth of the 80 million cars sold annually worldwide is fitted with engine control units made in Hatvan.

|

The plant is able to quickly adapt to customer demand with its highly-automated manufacture of engine control units and flexible production technology. 70 percent of all parts made in Hatvan are fitted on printed circuits.

|

The Hatvan plant also manufactured radar sensors for adaptive cruise control systems. The LRR (Long Range Radar) system works within 250 metres of the car in front, and are fitted in premium models such as the Audi A8 and the Porsche Cayenne. 45,000 such units are made every month at the plant.

|

The MRR (Mid Range Radar) system works within a range of 150 metres, and 50,000 units are manufactured every month. The MRR system is fitted into VW, Chrysler, Nissan and Honda cars.

|

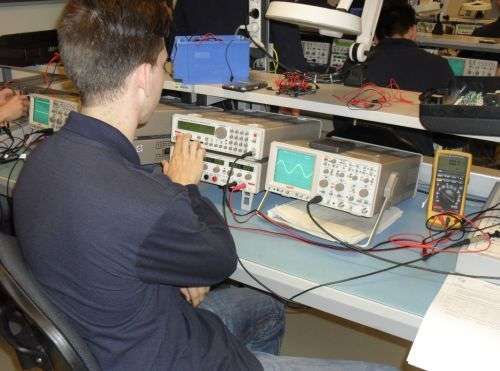

Dual education system has been introduced based on the German model. Training began with short trainings in cooperation with a local vocational school, which was followed by two basic trainings. Today, 14 students study electronics at Petőfi Sándor Technological Vocational School and 14 students study mechatronics at Damjanich János Vocational School.

|

The practical courses are taught by the company's professionals from these fields. A two-year course prepares the students for the positions of mechanic and machine operator.

|

Practical training in both courses involves a student contract with Robert Bosch Elektronikai Kft.'s Hatvan site. The students receive grants, opportunities to improve their language skills and a supplementary Bosch certificate besides their technician certificate. Last year, 89 percent of the graduates were hired by the Hatvan plant.

|